Intellectual Property

For the invention of this mobile disinfection system using UV-C, 1ventive filed on July 4, 2022 a patent application with the INPI (French patent office). On January 23, 2023, INPI communicated a preliminary search report declaring that all the claims present a character of novelty, inventive step, and possibility of industrial applications. The report has not identified prior art documents of particular relevance. This patent application published under the reference FR3127890A1 on April 14, 2023 is accessible from databases, such as Google Patents, PatentScope or Espacenet for example, where it is possible to translate the text into different languages.

Download patent application publication FR3127890A1 (in French)

This patent application is also published by the WIPO (World Intellectual Property Organization) with reference WO2023/247802A1.

Download the international publication WO2023/247802A1

1ventive does not plan to exploit directly this invention and is open to transfer all the intellectual property rights of the patent application FR3127890A1 (contact).

Principle

This mobile unit makes it possible to sanitize a surface thanks to the germicidal properties of UV-C, this operation having to be carried out under the best safety conditions for the user and surroundings.

UV-C rays are effective against a wide range of pathogenic microorganisms, but they also have the disadvantage of being able to damage living tissues. It is therefore essential to prevent parts of the human body from being exposed to this radiation, which is hazardous for the skin and eyes.

Consequently, the adopted solution consists of carrying out the UV-C operation within a closed enclosure.

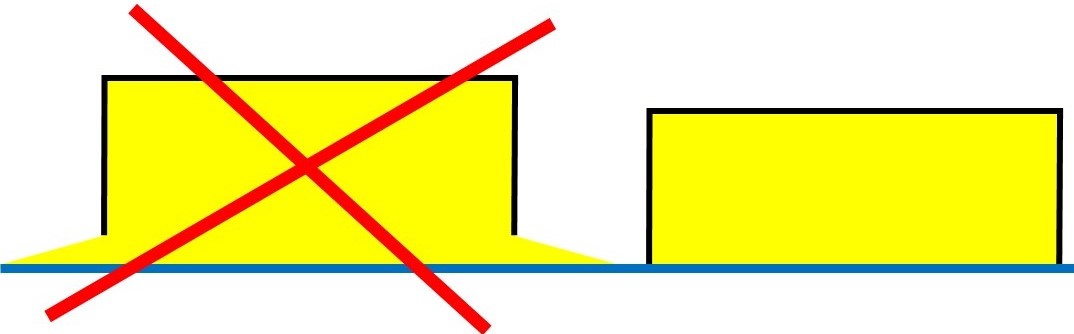

This principle leads to the use of a radiation enclosure where the UV-Cs are only activated when the enclosure is pressed against the surface to be treated. The enclosure has an opening on its base that allows UV-C to pass through :

To avoid damaging the surface to be treated, it is preferable to have the radiation enclosure not in direct contact with the surface while the system is in motion. Movement can be accomplished easily using wheels. However, it may be wise to have these wheels inside the radiation enclosure so that they can also be disinfected, thus avoiding the dispersion of any germs or viruses that could be on the wheels.

The invention is made up of a mobile carriage, a skirt that is pulled up when the carriage is moving and lowered when UV-C is radiated to disinfect the surface under the skirt. This acts as security for the user.

When the system is positioned on the area to be disinfected, the proposed solution consists of raising the wheels until they no longer touch the surface. That way, the radiation enclosure lowers to form a closed enclosure with the surface to be treated. The target surface is then disinfected with UV-C, and the wheels are also disinfected.

Extension mechanism

A device moving on a floor requires a certain height space because, in addition to the UV-C source, it must also embed the control system allowing movement as well as various detection and positioning sensors. A variant of the invention has the UV-C source in a drawer that is connected to the skirt and turned towards the ground. This position allows the UV-C source to be moved to areas where the device couldn’t reach because it was too high.

UV-C sources

Following frequent on/off operations, the operation of some UV-C sources may degrade. It is suggested that these sources be interrupted by using a mechanical cover acting as a mask, however the complete extinction of the sources remains possible during voluntary shutdowns or in emergencies.

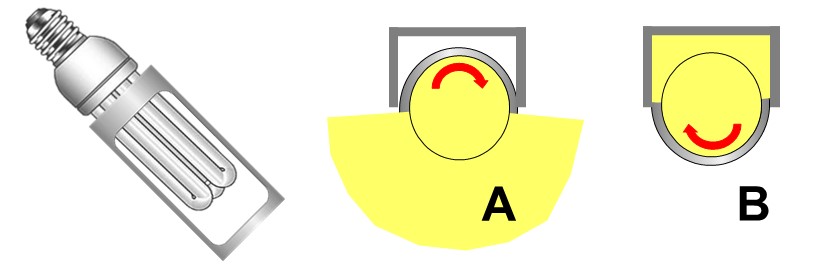

Example: The lamp can be placed in a case with an opening, so that at a certain position of the case, the radiation is free to propagate in the enclosure and towards the surface to be treated (case A of the figure below) whereas, in an alternative position of the case, the radiation is confined and does not radiate in the enclosure (case B of the figure below).

Ozone (characteristics, generation, constraints)

The use of ozone is another known method of disinfection and treatment of bad odors. Ozone is a very effective germicide against bacteria and viruses, but it is a gas that can penetrate the thickness of the surface not directly exposed to UV-C (for example, porous or fibrous materials). Ozone also can neutralize organic compounds, sources of bad odors and therefore act as a deodorization method.

It is possible to enrich the ambient air under the mobile unit with ozone generated by UV-C radiation at a wavelength of 185 nm. The oxygen molecules “O2” are then split by the radiation to recombine into “O3” molecules (ozone). This ozone is unstable and is quickly transformed back into oxygen “O2” .

However, it is important to note that at certain wavelengths UV-C can generate ozone, but at other wavelengths UV-C destroys ozone, it is for example noted the existence of an ozone generation peak at 185 nm, and an ozone destruction peak at 254 nm. To operate effectively, it is therefore essential to avoid working simultaneously with these two wavelengths. If UV-C sources at different wavelengths are used, the invention makes it possible to turn on their radiation independently.

Presence sensor

To minimize the risks for the user, the generation of UV-C is carried out in a closed enclosure in a lowered position. After lifting-up, the enclosure moves successively towards each surface element to be treated. Because of this, this procedure can be quite lengthy to treat a large surface.

The absence of living beings in the surroundings can be detected, so it is not necessary for UV-C to be generated in a closed enclosure when the mobile disinfection system is a robot that can operate autonomously. When moving over the entire surface to be treated, instead of proceeding in successive stages, disinfection can take place more quickly and in a continuous manner. The presence sensor allows the control of the operation of the system in one mode or another (successive stages of disinfection, or continuous disinfection).

Summary of benefits

- Mobile surface disinfection system,

- Treatment without the use of liquid chemicals,

- Reduction of health risks (the system is pressed against the surface to be treated, preventing the spread of UV-C radiation outside the enclosure),

- External treatment of the surface by direct exposure to UV-C, and in depth (porous or fibrous materials) by generation of air enriched with ozone (disinfection and deodorization),

- Limitation of the risks of damaging the surface by using wheels that raise the system when it moves,

- Wheels retracted in the enclosure during disinfection operations (prevents a possible spread of contamination by the wheels during motion),

- Disinfection drawer lowered to access areas with limited height,

- Minimization of the number of on/off cycles (mechanical cover) to avoid altering too much the operation of certain UV-C sources,

- Possibility of independent activation of the radiation of multiple UV-C sources,

- Depletion of ozone in the air by sequential activation of radiation at different wavelengths and ending with the activation of UV-C at 254 nm,

- Improvement of the global treatment time of an area by operating in continuous mode (disinfection while moving) when there are no living beings around the system.

Usage example (non-exhaustive list)

- Integrated disinfection in a vacuum robot,

- Disinfection of impermeable floor coverings (tiles, linoleum, etc.) or porous flooring (parquet floors, rugs, fitted carpets, etc.

- Deodorization of residential floors after pet urination / defecation, or because of traces of humidity,

- Disinfection and deodorization of floor mats used for sports activities (contact with sweat).

- …